The Project

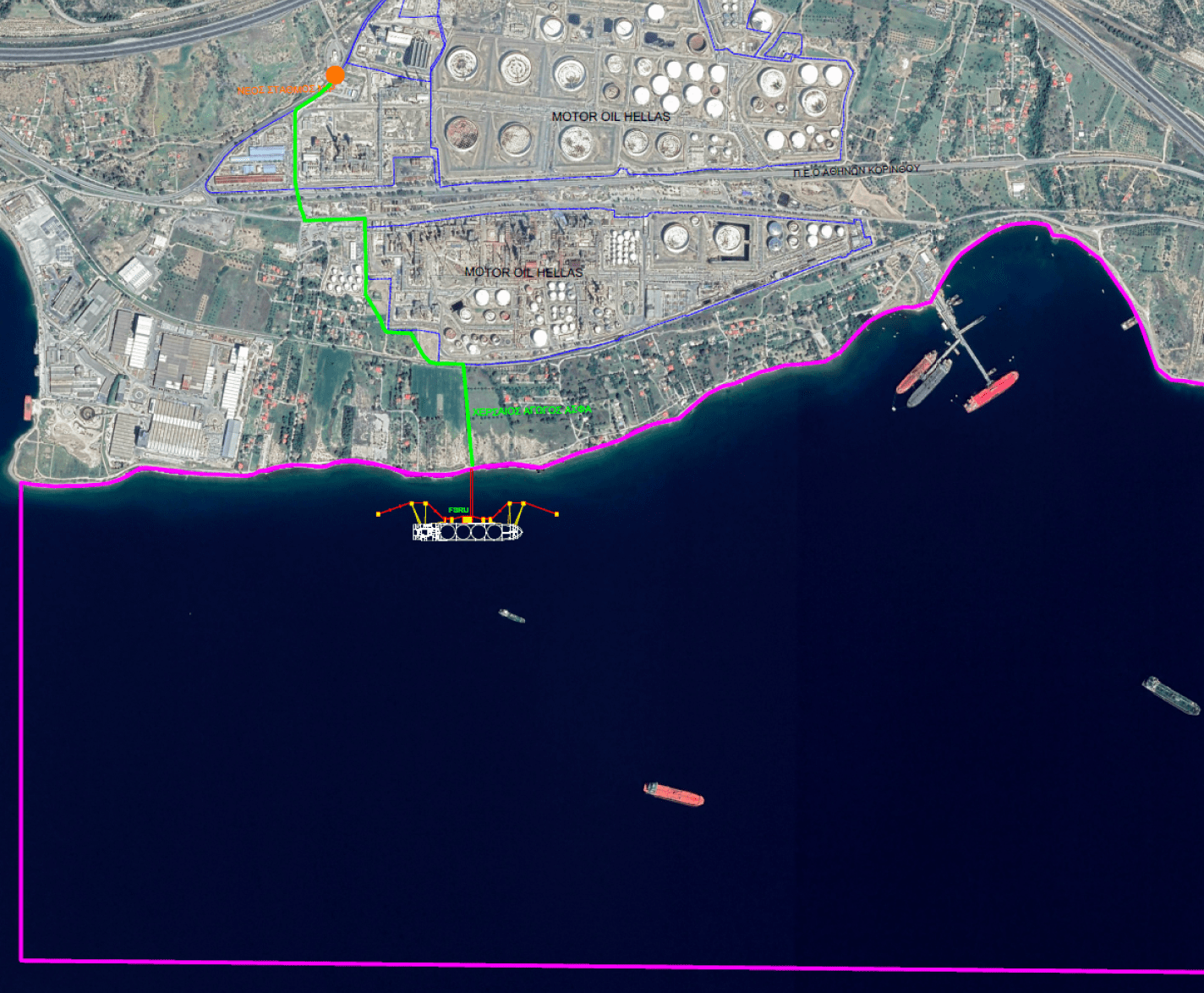

The terminal will be located at about 70 km away from Athens, in the area “Agioi Theodori” of the Regional District of Corinth, near Motor Oil’s refinery and at a distance of about 1.5 – 2 km from the NNGS, aiming to facilitate companies with interest in importing LNG to Greece through an additional major natural gas gateway to the NNGS.

Dioriga Gas will be a near shore LNG (Liquified Natural Gas) import terminal based on the Floating Storage and Regasification Unit (FSRU) configuration. LNG will be imported via LNG Carriers (LNGCs), stored in the floating unit’s cryogenic storage tanks, and either regasified in the floating unit and exported as natural gas (NG) to the Greek National Natural Gas Transmission System (NNGTS) or directly exported as LNG via LNG bunkering vessels and LNG trucks for road transportation.

The terminal will consist of the following main components

FSRU

An FSRU of maximum storage capacity up to 210.000 m3 LNG, will serve for the reception, storage and regasification of LNG that will be transported to the floating unit from LNGCs (of maximum capacity of 266,000 m3 LNG). LNGCs shall be moored side by side to the FSRU in order to feed LNG to FSRU cryogenic storage tanks via Ship to Ship transfer.

Jetty

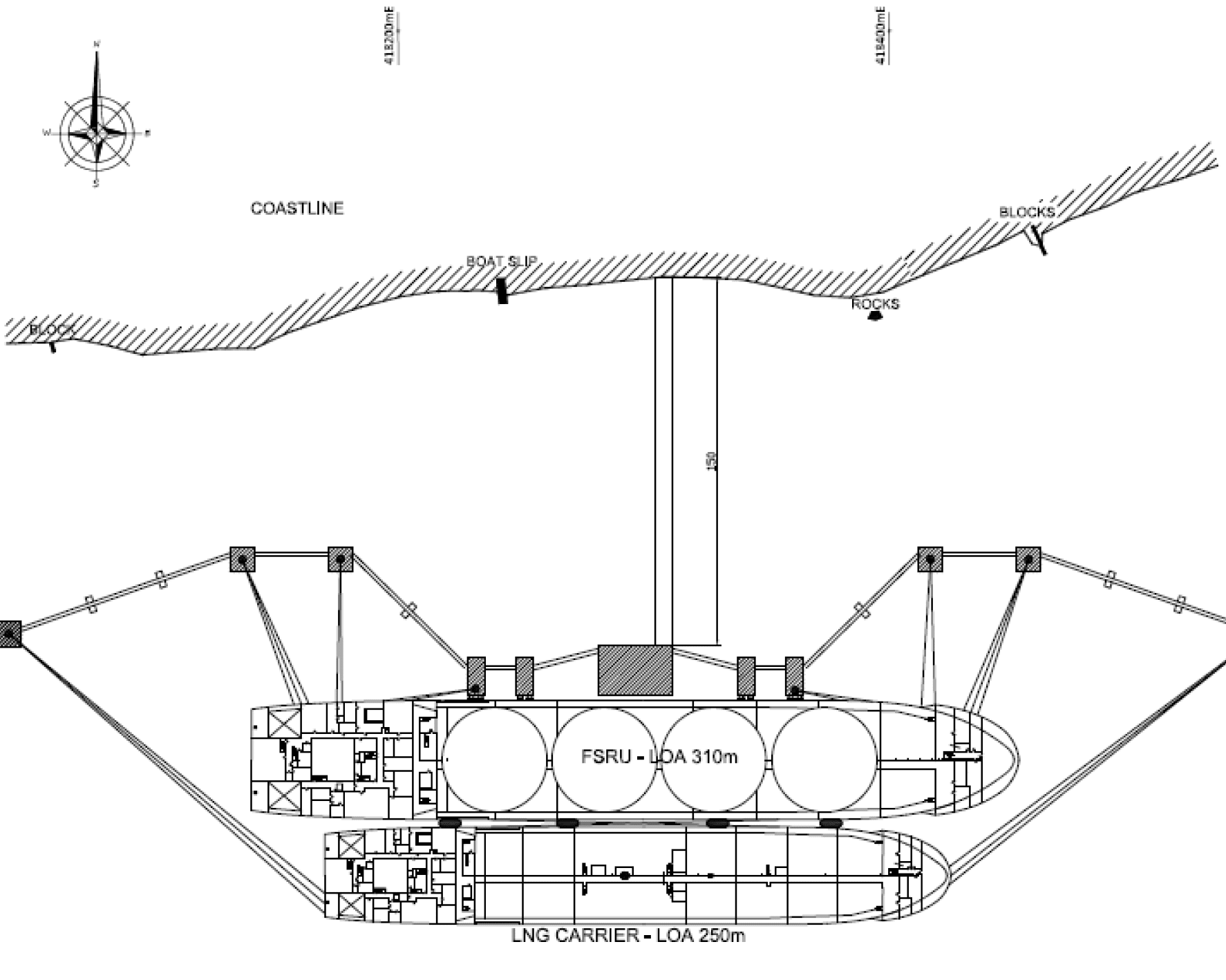

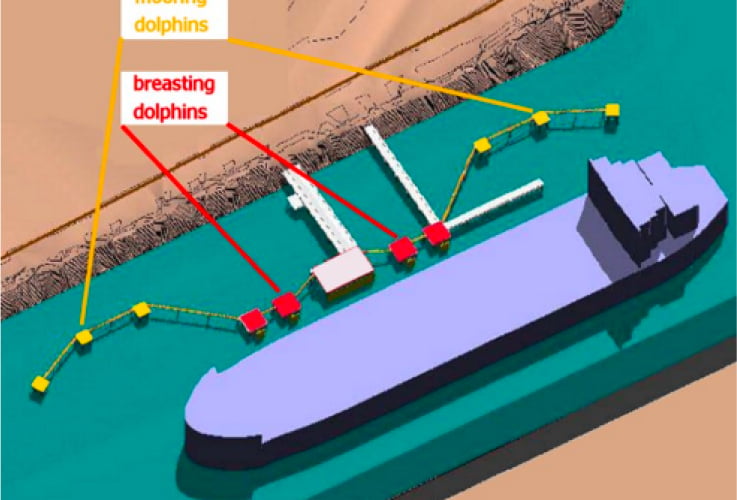

A jetty/ trestle, including a central platform, breasting and mooring dolphins, for the permanent berthing of the FSRU at about 150 m from the coastline and at depths of up to 25 m Mean Sea Level. The jetty will host both the NG and the LNG send-out line to the shore and will also serve the access of equipment and personnel transport vehicles.

Onshore Installation

Onshore installations including a high-pressure NG pipeline (that will be constructed with possibility to accept 100% hydrogen) and a Metering & Regulating Station for the NG injection to the NNGTS, as well as an LNG truck loading facility.

Preliminary Design Parameters

- Capacity of the FSRU cryogenic storage tanks: up to 210,000 m3 LNG

- Maximum send-out rate of NG to the NNGS: 132,000 MWh/day

- LNG unloading rate from the LNGC to the FSRU: up to 10,000 m3/hr LNG

- LNG reloading rate from the FSRU to LNG bunkering vessels: up to 1,500 m3/hr LNG

- LNG truck loading capacity: 24 trucks/day

Dioriga Gas FSRU contributes in improving the Security of Supply both of the country and the regional markets

The terminal will have the ability to receive LNG from several countries, such as: Algeria, Egypt, Equatorial Guinea, Nigeria, Norway, Peru, Qatar, Trinidad & Tobago, USA and cargoes coming from other European terminals such as Spain, Belgium and Netherland.

The projected jetty infrastructure works include briefly the following

- Utility platform of typical dimensions 15m x 20m

- Four (4) breasting dolphins of typical dimensions 7m x 15m. On these dolphins, there will be positioned marine fenders to absorb the berthing energy and movements of the ship in service.

- Six (6) mooring dolphins, of typical dimensions 10m x 10m in symmetrical layout of three (3) on each side and at a distance of 50m behind the berthing line. Quick Release Mooring Hooks (QRMH) will be placed on each dolphin.

- Access corridor to the coast of about 130 m long on which the gas pipelines will be heading towards the coast.

Maximum Length

Lmax=315m

Maximum Width

Βmax= 50m

Maximum Width

Dmax= 14m

The plant can receive LNG from LNG carriers at a maximum flow rate of 10,000 m3/hr. LNGC shall be moored side by side to the FSRU in order to transfer LNG (Ship to Ship) via flexible hoses to FSRU storage tanks. A typical flow diagram of the whole process with focus on the regasification is presented in the figure below:

“To increase the availability of the Terminal and to adapt it to the new market conditions, Dioriga Gas FSRU keeps up to date with the world wide guidelines maximizing the authorized LNG cargoes receivable from the worldwide LNGc fleet, keeping unchanged the maximum authorized annual regasification capacity of 4bcm of natural gas. This flexibility allows the users of the Terminal to take advantages from the opportunities that, will involve the Mediterranean area, for the forthcoming years.

Before the discharge, every LNG carrier is subject to a technical compatibility process, where all the technical characteristics are assessed. Once the assessment is completed, the ship is added to the list of approved carriers (published on the Services area of DG’s website).